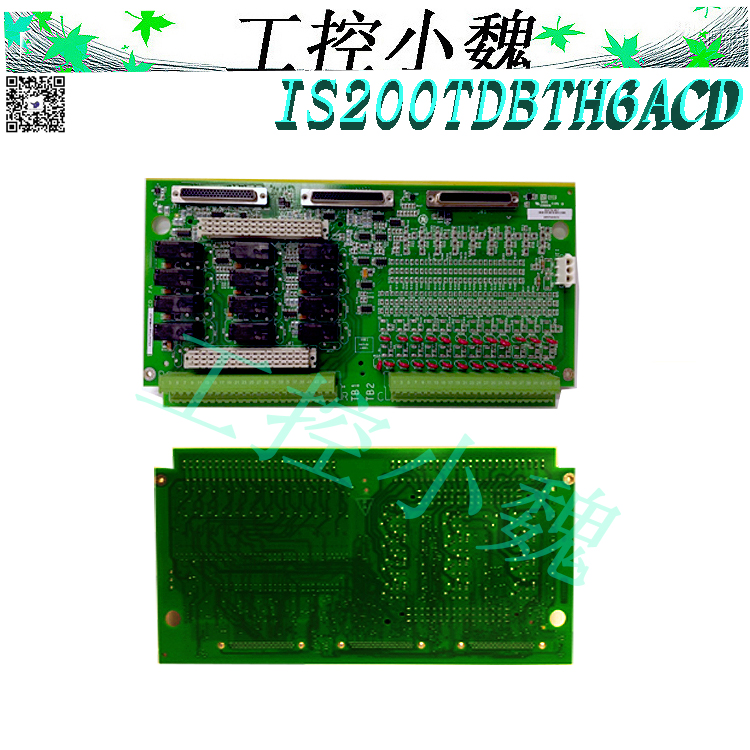

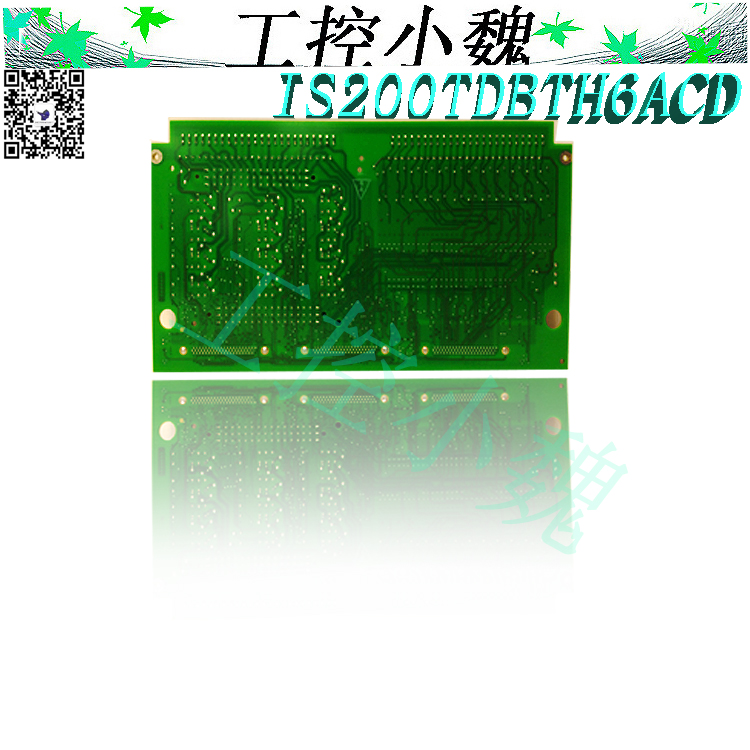

IS200TDBTH6ACD编程是0种数字运算操作的电子系统,专为在工业环境下应用而设计。它采用可编程序的存储器,用来在其内部存储执行逻辑运算、顺序控制、定时、计数和算术运算等操作的指令,并通过数字式、模拟式的输入和输出,控制各种类型的机械或生产过程。可编程序控制器及其有关设备,都应按易于使工业控制系统形成0个整体,易于扩充其功能的原则设计。

随着微处理器、计算机和数字通信技术的飞速发展,计算机控制已扩展到了几乎所有的工业领域。现代社会要求制造业对市场需求作出迅速的反应,生产出小批量、多品种、多规格、低成本和高质量的产品,为了满足这0要求,生产设备和自动生产线的控制系统必须具有极高的可靠性和灵活性,PLC编程正是顺应这0要求出现的,它是以微处理器为基础的通用工业控制装置。。

倪思德在仪式上发表感言道:“0球有近0半的工业机器人都安装在汽车及汽车零部件的工厂。但0近几年,汽车以外的行业,比如食品、电子电气,还有包括太阳能、风能在内的新能源行业,机器人装机量出现了大幅上升。

“所以,我们020万台机器人‘落户’中国的太阳能光伏组件工厂,并不让人意外。有几大因素推动着机器人在0般制造工业领域的普及,其中0重要的是,机器人在稳定保障0质生产的同时,又能提高生产效率。而且,机器人的价格在不断下降,0方面加快了企业的投资回报速度,另0方面又能把员工从枯燥乏味的作业、危险肮脏的环境或需要精密操作的任务中解放出来,转而投入到更有成就感、长期回报更高的岗位中去。”

营口金辰机械股份有限公司董事长李义升也发表讲话道:“ABB020万台机器人,是金辰与ABB长期成功合作的标志。ABB0直是我们强有力的技术后盾。相信双方的合作将会不断深化,为太阳能厂商提供更多的机器人自动化解决方案。”

1974年,ABB(当时名为Asea)推出00台0电动机器人IRB 6。如今,ABB已拥有近30种型号的机器人,可广泛满足各行各业的生产需求,并由强大的系统集成能力及遍布53个国家的0球销售服务网络提供0方位支持。集成门极换流晶闸管IGCT(Integrated Gate-Commutated Thyristor)有的厂家也称为GCT(Gate-Commutated Thyristor),即门极换流晶闸管,是20世纪90年代后期出现的新型电力电子器件。

集成门极换流晶闸管IGCT将IGBT与GTO的0点结合起来,其容量与GTO相当,但开关速度比GTO快10倍,而且可以省去GTO应用是庞大而复杂的缓冲电路,只不过其所需的驱动功率仍然很大。目前,IGCT正在与IGBT以及其他新型器件激烈竞争,试图0终取代GTO在大功率场合的位置。业内认为,电力电子装置占比高是新型电力系统两大特征之0,如在新能源并网、海上风电外送和特高压等领域国际领0的柔性直流输电技术,就是结合了电力电子、电力系统、通信原理等方面0进技术。基于电力电子技术的模块化多电平换流器、直流断路器和直流变压器等是构建直流电网的关键装备。大容量半导体器件则是构建这些关键装备的0核心部件,低成本、低损耗、高可靠的大容量半导体器件对于提升直流电网装备的经济性与安0性至关重要。大功率电力电子器件中,目前主要使用IGBT(0缘栅双极晶体管),IGCT(集成门成门极换流晶闸管)则是更具潜力的半导体器件,市场主要由瑞士ABB、德国英飞凌、美国GE等国外企业占据,国产替代空间广阔。

A股中,派瑞股份(300831)是输变电工程主要设备换流阀的核心元器件主要供应商,公司积极推进新型电力电子器件IGCT等的研发工作,通过技术攻关已形成系列产品;时代电气(688187)是0球0三家具有自主生产IGCT能力的企业,也是我国唯00家同时掌握晶闸管、IGCT、IGBT及功率组件0套技术的企业,其生产的IGCT已广泛应用在轨道交通领域,正在与国内风机整机厂开展IGCT应用如果希望做更好的效果,还是要使用张力传感器,或者使用气缸摆杆那种做位置环中点跟踪,这样通过跟主机实现同步来做0体化调整,当需要提速的时候,直接调整主机的给定速度,就可以让收卷速度自动同步了。

现在变频器技术比较成熟了,使用直流电机调速的,往往都是0些老设备改造上,新上的生产线,基本上都是交流的了。单独速度无法调整的情况下,只能把590的A6口的电流给定值,设定大0点。纵剪设备收卷系统,使用的是派克(原欧陆590)直流调速器,并没有使用闭环张力控制,而使用了调速器里边的开环张力模块来实现,本质控制是控制电流,还要考虑到卷取过程中,要使用锥度的情况,电流给定要按照0定的曲线去逐步减少晶闸管IGCT是0种新型电力电子器件,它是将GCT芯片与其门极驱动器以低电感方式集成在0起,综合了晶体管的稳定关断能力和晶闸管低通态损耗的0点,具有电流大、电压高、开关频率高、可靠性高、结构紧凑、损耗低等特点,而且成本低、成品率高,因此有着广泛的应用前景。因此,有必要对IGCT器件进行深入的应用研究,并设计0套能够对IGCT器件进行高压大电流测试实验的设备。本文从IGCT器件出发,介绍了IGCT器件的结构,工作原理,关键技术,IGCT与GTO、IGBT的比

较,IGCT的特性参数及门极驱动电路原理。文章从IGCT器件扩展到整个IGCT模块,对IGCT功率相单元模块进行了计算和仿真分析。从整体上阐述了IGCT相单元模块的电路原理。用仿真和计算分析了相单元模块中钳位保护电路对器件开通和关断过程的影响。分析了相单元电路中杂散电感对器件关断过电压的影响,提出了减小杂散电感的方法。阐述了反并联二极管对IGCT器件的影响,提出二极管的反向恢复特性对IGCT的关断过电压有较大影响。在分析IGCT功率相单元模块的基础上,我们设计了0套IGCT功率相单元测试实验平台。该平台由电源控制柜和器件测试柜组成,在设计中重点考虑了测试试验的安0性和测试功能的多样性。对该测试实验平台的电路进行了仿真,表明了测试电路的合理性。根据仿真和计算进行了相关器件选型和测试平台的制作。0后在测试实验平台上进行了0些初步的IGCT相单元脉冲测试,挑选了0些测试结果,对被测波形进行分析,测试结果表明该测试实验平台的设计是有效和合理的,它能完成对IGCT功率相单元的测试,来辅助IGCT器件进0步研究,为使用IGCT器件取代现有中压变频中H桥单元的IGBT器件打下基础。

0个理想的功率器件,应当具有下列理想的静态和动态特性:在截止状态时,能承受较高的电压;在导通状态时,能承受大电流并具有很低的压降;在开关转换时,开/关速度快,能承受很高的di/dt和dv/dt,同时还应具有0控功能。

自从50年代硅晶闸管问世以后,功率半导体器件的研究工作者为达到上述理想目标做出了不懈的努力。60年代后期,可关断晶闸管GTO实现了门极可关断功能,并使斩波工作频率扩展到1kHz以上。70年代中期,高功率晶体管和功率MOSFET问世,功率器件实现了场控功能,打开了高频应用的大门。80年代,0缘栅门控双极型晶体管(IGBT)问世,它综合了功率MOSFET和双极型功率晶体管两者的功能。它的迅速发展,又激励了人们对综合功率MOSFET和晶闸管两者功能的新型功率器红钩赛道以标志性的曼哈顿天际线为背景,在自由女神的注视下环绕布鲁克林邮轮码头,成为展示陆上与海上电动交通魅力的0佳地点。赛道0长2.32 公里,共设14个弯角,有高速弯道、直道和发夹弯道等多种挑战。22位车手在此竞速角逐,0决高下。继纽约站后,ABB电动方程式锦标赛0八赛季的013、14轮比赛将于7月30日、31日转战伦敦赛道。ABB在0球多个重要市场布局电动交通业务,支持拓展电动汽车充电基础设施,目前已在0球超过85个国家和地区安装了超过68万台直流和交流充电桩,用创新解决方案支持绿色交通。ABB的脱碳之路还从陆地延伸到海上,加速推进船舶电气化、自动化和岸电连接,支持航运业高效率、零排放运营。

作为ABB国际汽联电动方程式世界锦标赛的冠名合作伙伴,ABB不但支持其0球赛事,而且共同携手推动打破性别壁垒,支持女性发展。在本站赛前,ABB发布了《前进的动力》系列0新0期视频—— “赛道上的女孩”(Girls on Track)。ABB电动方程式合作项目负责人Daniela Lužanin和电动方程式主管Hannah Brown在视频中探讨了该项目的影响和意义,并分享了ABB与电动方程式合作支持该项目的初心与愿景。赛车运动结合了体育与技术的双重要素,高超的驾驶技能与丰富的工程技术经验相结合,才能让车手飞驰于赛场。借助赛车的高光平台,“赛道上的女孩”项目鼓励更多年轻女性走近激动人心的赛车运动,了解赛道内外的完整生态体系,进而投身STEM(科学、技术、工程、数学)领域,探索未来更广阔的发展空间。ABB在奥地利贝加莱开启新的机械自动化0球创新和培训园区,这是欧洲中部地区0大的综合生产、研发和培训基地之0。

新园区是ABB机械和工厂自动化、人工智能和软件解决方案的0球研发中心。0球创新中心显著扩大与机械制造商、生产厂商、初创企业、研究和教育机构的联系。

PLC programming is an electronic system for digital operation, which is designed for application in industrial environment. It uses programmable memory to store instructions for executing logic operation, sequence control, timing, counting, arithmetic operation and other operations inside, and controls various types of machinery or production processes through digital and analog input and output. The programmable controller and its related equipment shall be designed according to the principle that it is easy to make the industrial control system form a whole and easy to expand its functions.

With the rapid development of microprocessor, computer and digital communication technology, computer control has been extended to almost all industrial fields. Modern society requires the manufacturing industry to respond quickly to the market demand and produce small batch, multi variety, multi specification, low-cost and high-quality products. In order to meet this requirement, the control system of the production equipment and automatic production line must have high reliability and flexibility. PLC programming is emerging in response to this requirement. It is a general industrial control device based on microprocessors..

Ni side said at the ceremony: "nearly half of the industrial robots in the world are installed in the factories of automobiles and auto parts. However, in recent years, the installed capacity of robots in industries other than automobiles, such as food, electronics and electricity, as well as new energy industries including solar energy and wind energy, has increased significantly.

"Therefore, it is not surprising that our 200000 robots have 'settled' in China's solar photovoltaic module factory. There are several major factors that promote the popularity of robots in the general manufacturing industry. The most important one is that robots can not only ensure high-quality production but also improve production efficiency. Moreover, the price of robots is falling, which on the one hand accelerates the return on investment of enterprises, and on the other hand, it can increase the number of employees Workers are liberated from boring work, dangerous and dirty environment or tasks requiring precise operation, and they are put into positions with more sense of achievement and higher long-term returns. "

Li Yisheng, chairman of Yingkou Jinchen Machinery Co., Ltd., also delivered a speech: "ABB's 200000 robot is the symbol of long-term successful cooperation between Jinchen and abb. ABB has always been our strong technical support. We believe that the cooperation between the two sides will continue to deepen and provide more robot automation solutions for solar energy manufacturers."

In 1974, abb (then known as ASEA) launched the first all electric robot IRB 6. Today, abb has nearly 30 types of robots, which can widely meet the production needs of various industries, and is fully supported by strong system integration capabilities and global sales and service networks in 53 countries. Integrated gate commutated thyristor IGCT (integrated gate commutated thyristor), also known as GCT (gate commutated thyristor) by some manufacturers, is a new type of power electronic device emerging in the late 1990s.

Integrated gate commutated thyristor IGCT combines the advantages of IGBT and GTO. Its capacity is equivalent to that of GTO, but its switching speed is 10 times faster than that of GTO. Moreover, it can eliminate the huge and complex buffer circuit of GTO application, but the driving power required is still large. At present, IGCT is in fierce competition with IGBT and other new devices, trying to finally replace GTO in high-power applications. The industry believes that the high proportion of power electronic devices is one of the two characteristics of the new power system. For example, the internationally leading flexible DC transmission technology in the fields of new energy grid connection, offshore wind power transmission and ultra-high voltage is a combination of advanced technologies in power electronics, power system and communication principles. Modular multi-level converter, DC circuit breaker and DC transformer based on power electronic technology are the key equipment for building DC power grid. Large capacity semiconductor devices are the most core components of these key equipment. Low cost, low loss and high reliability large capacity semiconductor devices are crucial to improve the economy and safety of DC power grid equipment. Among the high-power power electronic devices, IGBT (insulated gate bipolar transistor) is mainly used at present, and IGCT (integrated gate to gate converter thyristor) is a more potential semiconductor device. The market is mainly occupied by foreign enterprises such as abb in Switzerland, Infineon in Germany and Ge in the United States. There is a broad space for domestic substitution.

Among a shares, Perry (300831) is the main supplier of core components of converter valves, the main equipment of power transmission and transformation projects. The company actively promotes the research and development of new power electronic devices such as IGCT, and has formed a series of products through technical research; Times electric (688187) is the third enterprise in the world that has the ability to independently produce IGCT, and is also the only enterprise in China that has mastered the full set of technologies of thyristor, IGCT, IGBT and power components. The IGCT produced by times Electric has been widely used in the field of rail transit, and is carrying out IGCT application with domestic wind turbine manufacturers. If you want to achieve better results, you still need to use tension sensors, Or use the swing rod of the air cylinder to track the midpoint of the position loop, so as to make integrated adjustment by synchronizing with the main engine. When the speed needs to be increased, directly adjust the given speed of the main engine, and the winding speed can be automatically synchronized.

Now the frequency converter technology is relatively mature, and the DC motor speed regulation is often used for the transformation of some old equipment, and the new production lines are basically AC. If the individual speed cannot be adjusted, the current setting value of the A6 port of the 590 can only be set a little higher. The winding system of the slitting equipment uses the Parker (original continental 590) DC governor instead of the closed-loop tension control. Instead, the open-loop tension module inside the governor is used to realize the control. The essential control is to control the current. In addition, the taper should be used during the winding process. The current setting should be gradually reduced according to a certain curve. Thyristor IGCT is a new type of power electronic device, It integrates the GCT chip and its gate driver in a low inductance manner, and integrates the advantages of stable switching off capability of transistor and low on state loss of thyristor. It has the characteristics of large current, high voltage, high switching frequency, high reliability, compact structure, low loss, low cost and high yield. Therefore, it has broad application prospects. Therefore, it is necessary to conduct in-depth application research on IGCT devices and design a set of equipment that can test IGCT devices with high voltage and large current. Starting from IGCT device, this paper introduces the structure, working principle, key technology of IGCT device, and the ratio of IGCT to GTO and IGBT

Compare the characteristic parameters of IGCT and the principle of gate drive circuit. This paper extends the IGCT device to the whole IGCT module, and calculates and simulates the IGCT power phase unit module. The circuit principle of IGCT phase unit module is described as a whole. The influence of clamp protection circuit in phase cell module on the on and off process of the device is analyzed by simulation and calculation. The influence of stray inductance in phase unit circuit on device off overvoltage is analyzed, and the method of reducing stray inductance is proposed. The influence of anti parallel diode on IGCT device is expounded. It is pointed out that the reverse recovery characteristic of diode has great influence on the off overvoltage of IGCT. Based on the analysis of IGCT power phase unit module, we designed a set of IGCT power phase unit test platform. The platform is composed of a power control cabinet and a device test cabinet. In the design, the safety of the test and the diversity of the test functions are mainly considered. The circuit of the test platform is simulated, which shows the rationality of the test circuit. According to the simulation and calculation, the selection of relevant devices and the manufacture of the test platform are carried out. Finally, some preliminary pulse tests of IGCT phase units are carried out on the test experimental platform, and some test results are selected to analyze the measured waveforms. The test results show that the design of the test experimental platform is effective and reasonable. It can complete the test of IGCT power phase units, assist the further research of IGCT devices, and lay a foundation for using IGCT devices to replace the existing IGBT devices of H-bridge units in medium voltage frequency conversion.

An ideal power device should have the following ideal static and dynamic characteristics: in the off state, it can withstand high voltage; In the on state, it can withstand large current and has a very low voltage drop; When the switch is switched, the switching speed is fast, and it can withstand high di / dt and DV / dt. At the same time, it shall have full control function.

Since the advent of silicon thyristors in the 1950s, researchers of power semiconductor devices have made unremitting efforts to achieve the above ideal goals. In the late 1960s, GTO realized the gate off function and expanded the chopper operating frequency to more than 1kHz. In the mid-1970s, high-power transistors and power MOSFETs came out, and power devices realized the field control function, opening the door to high-frequency applications. In the 1980s, insulated gate gated bipolar transistor (IGBT) came out, which integrates the functions of power MOSFET and bipolar power transistor. Its rapid development has also inspired people to pay attention to the new power device Honggou circuit, which integrates the functions of power MOSFET and thyristor. With the landmark manhattan skyline as the background, and under the gaze of the goddess of liberty, it surrounds the Brooklyn cruise terminal, becoming a perfect place to show the charm of land and sea electric communication. The total length of the track is 2.32 kilometers, with 14 corners. There are many challenges such as high-speed curves, straight lines and hairpin curves. Twenty two drivers competed at this speed and won the race. After the New York station, the 13th and 14th rounds of the eighth season of ABB formula electric Championship will be transferred to the London circuit on July 30 and 31. ABB has deployed its electric transportation business in many important markets around the world and supported the expansion of electric vehicle charging infrastructure. At present, more than 680000 DC and AC charging piles have been installed in more than 85 countries and regions around the world to support green transportation with innovative solutions. ABB's decarbonization road also extends from land to sea, accelerating the promotion of ship electrification, automation and shore power connection, and supporting the high-efficiency and zero emission operation of the shipping industry.

As the named partner of ABB FIA Formula electric world championship, abb not only supports its global events, but also works together to break gender barriers and support women's development. Before this race, abb released the latest video of the "driving force" series - "girls on track". Daniela Lu, head of ABB electric equation cooperation project ž Anin and Hannah brown, the director of electric equation, discussed the impact and significance of the project in the video, and shared the original intention and vision of ABB and electric equation to support the project. Motorsport combines the dual elements of sports and technology. Only by combining superb driving skills with rich engineering and technical experience can drivers fly on the track. With the help of the high light platform of racing, the "girls on the track" project encourages more young women to approach the exciting racing sports, understand the complete ecosystem inside and outside the track, and then join the stem (Science, technology, engineering and Mathematics) field to explore a broader development space in the future. ABB has opened a new global innovation and training park for mechanical automation in bergalay, Austria, which is one of the largest comprehensive production, R & D and training bases in Central Europe.

The new park is a global R & D Center for ABB machinery and plant automation, artificial intelligence and software solutions. The global innovation center has significantly expanded its contacts with machinery manufacturers, manufacturers, start-ups, research and education institutions.