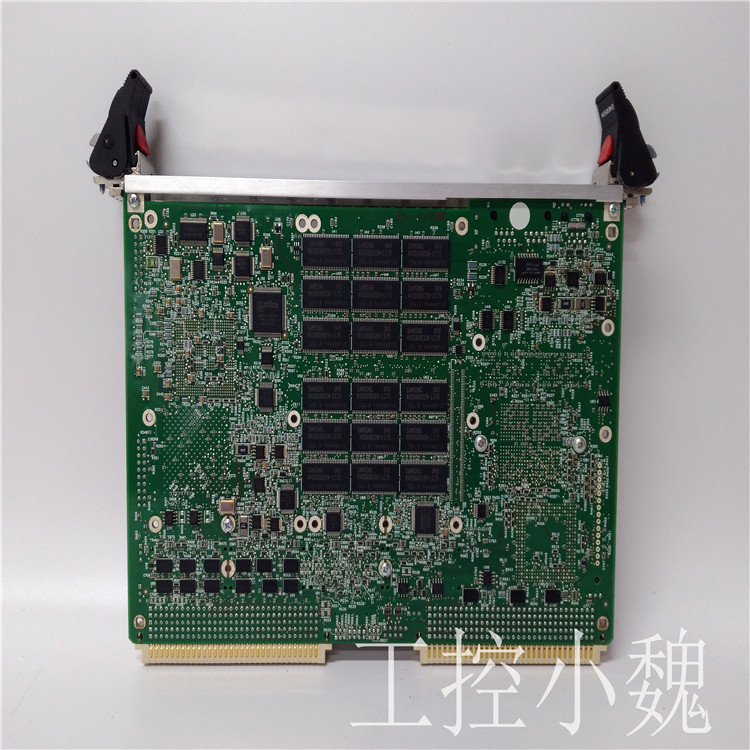

MVME55006E-0163通气

可编程序控制器的英文为Programmable Controller,在二十世纪70-80年代一直简称为PC。由于到90年代,个人计算机发展起来,也简称为PC;加之可编程序的概念所涵盖的范围太大,所以美国AB公司将可编程序控制器定名为可编程序逻辑控制器(PLC-Programmable Logic Controller),为了方便,仍简称PLC为可编程序控制器。有人把可编程序控制器组成的系统称为PCS可编程序控制系统,强调可编程序控制器生产厂商向人们提供的已是完整的系统了。

PLC的发展和市场情况

PLC的发展历史

1968年美国GM(通用汽车)公司提出取代继电器控制装置的要求,二年美国数字公司研制出了代可编程序控制器,满足了GM公司装配线的要求。随着集成电路技术和计算机技术的发展,现在已有五代PLC产品了。

在以改变几何形状和机械性能为特征的制造工业和以物理变化和化学变化将原料转化成产品为特征的过程工业中,除了以连续量为主的反馈控制外,特别在制造工业中存在了大量的开关量为主的开环的顺序控制,它按照逻辑条件进行顺序动作号按照时序动作;另外还有与顺序、时序无关的按照逻辑关系进行连锁保护动作的控制;以及大量的开关量、脉冲量、计时、计数器、模拟量的越限报警等状态量为主的—离散量的数据采集监视。由于这些控制和监视的要求,所以PLC发展成了取代继电器线路和进行顺序控制为主的产品。在多年的生产实践中,逐渐形成了PLC、DCS与IPC三足鼎立之势,还有其它的单回路智能式调节器等在市场上占一定的百分比。

HP AgilThe DeltaV™ SQ controllers provides communication and

control functions and integrate field devices and the other

nodes on the control network. The SX and SQ controllers

provide a choice to match the controller capacity to the

requirements of the process. They also provide new ease

of use features that eliminate mounting screws and accelerate

cabinet assembly.Control strategies and system configurations created on

earlier DeltaV systems can be used with this controller.

The SQ controller provides all the features and functions

of the M-series controllers including support for CHARM

based Electronic Marshalling.

The control languages executed in the controllers are

described in the control software product data sheet.Scalable controllers. The SQ controller complements the

SX controller by providing a smaller controller platform at

a reduced price for those small to moderate applications:

Speed. The SQ controller supports all the features you’ve

come to expect from the DeltaV system: self-addressing,

automatic I/O detection. All these features are designed

to make your projects execute faster — just plug and play!

Redundant Architecture. The SQ controller supports

1:1 redundancy for increased availability. Redundant SQ

controllers can be upgraded to SX controllers online — robust!

Late Changes. You can easily upgrade an SQ controller

to an SX to handle project scope changes late in the

project. Simply replace the SQ with the SX and all existing

configuration, documentation and hardware design remain

the same — forgivingControl modules are automatically scheduled by the controller,

based on their assigned scan rates. This allows each control

function to be optimized based on the process dynamics.

Modules scan times can be set as fast as 100 ms, and as slow

as 60 seconds. The number of control modules that can be

assigned to a controller depends on the complexity and scan

rate of each module, and the available CPU and memory.

The SQ controller should be used for small to medium

applications with a maximum of 750 individual I/O signals.

The SQ controller is designed for harsh environments and

is rated for G3 corrosive environments, with an operating

temperature range from -40 to 70°C. It is ideally suited for

remote installation, close to the process equipment. For more

traditional installations with central marshalling cabinets,

CHARM I/O Cards can be mounted in standard I/O cabinets

providing Electronic Marshalling. CHARM I/O Cards can also

be used for highly distributed I/O applications.除了传统的I/O卡,本地总线还支持

现场总线技术,

Profibus DP、DeviceNet和AS-i协议。I/O子系统

还支持串行接口卡和以太网I/O

界面这些不同的I/O产品提供了广泛的

接口,以满足控制应用程序的需要。

SQ控制器还支持CHARM和WirelessHART

I/O卡。CHARM I/O卡(CIOC)通过

控制器的冗余以太网端口,以提供

高度分布式和灵活的I/O解决方案,称为Electronic

编组。0多16个CIOC可以与一个

控制器,每个控制器提供多达96个可单独配置的

信号类型。

SQ控制器的容量限制可能因

在特定应用中,CHARM I/O信号的数量

以及控制性能要求。增强

内存处理和硬件警报,涵盖容量和

通过索引将内存添加到诊断信息中

SQ控制器。

无线HART I/O卡(WIOC)提供冗余

0多100个无线HART设备的通信,提供

无线数据的高可用性和可靠性。0多16个

无线HART I/O卡可以与一个控制器通信,

每个提供多达100个信号。The first firmware version for the PTQ-PDPMV1 that supported HSBY was version 1.15. That version and successive versions up until version 1.25 could support only one (1) PTQ-PDPMV1 module per HSBY CPU chassis. Starting with version 1.25 and later, you can have up to four (4) PTQ-PDPMV1 modules per HSBY chassis.