英维思(3008, 3625, 3508E.3721, 3700A 4351B)

本特利(3500/42M, 3500/ 22M, 3500/ 95.3500/05)

黑马(F3330, F3236, F6217, F7126, F8621A)

福克斯波罗(FBM203, FBM204, FBM217, FMB231)

AB: (1746 1747 1756 1770 1771 1785触摸屏2711系列CPU PLC)

普罗索芙特PROSOFT MVI46/56/69, AB旗下,跟AB模块

瑞恩RELIANCE模块,卡件

飞利浦EPRO MMS6210/ 621…. PR6423/003-031

美尔托Meltal MT1102-02-00, MS3101-00-00, MS3102-01-00

横河YOKOGAWA AAI, ADV, ADI, ANB, AMM, SB, PW(型号开头),卡件模块(CPU,电源,输出,PLC)

摩尔MOORE Q开头, 3开头模块,像电视显示器Design content of PLC control system

(1) According to the design specification, carry out process analysis and determine the control scheme, which is the basis of the design.

(2) Select input devices (such as buttons, switches, sensors, etc.) and output devices (such as relays, contactors, indicator lights and other actuators).

(3) Select the model of PLC (including model, capacity, I / O module and power supply, etc.).

(4) Allocate I / O points of PLC and draw I / O hardware wiring diagram of PLC.

(5) Write programs and debug.

(6) Design the operation console, electrical control cabinet, etc. of the control system and the installation wiring diagram.

(7) Prepare design instructions and operation instructions.

Labor shortage, talent shortage and high risk factor are common problems in the traditional construction industry. Production automation has become one of the reliable solutions at present. Robot automation can improve the safety, sustainability and cost-effectiveness of the industry. In the past year, abb has been committed to improving the production flexibility, efficiency and quality of the construction industry, and its application in the construction field has been continuously expanded. At present, a large number of innovative applications have been put into use. Programmable controller is an electronic system of digital operation, which is specially designed for application in industrial environment. It adopts programmable memory, which is used to store instructions for executing logical operations, sequence control, timing, calculation and arithmetic operations, and control various types of machinery or production processes through digital and analog input and output. PLC is the product of the combination of microcomputer technology and traditional relay contact control technology. It overcomes the shortcomings of complex wiring, low reliability, high power consumption, poor versatility and flexibility of mechanical contacts in relay contact control system, and makes full use of the advantages of microprocessor. The programmable controller is a non-contact device for the user, and the production process can be changed by changing the program. Therefore, the programmable controller can be selected in the preliminary design stage and the process can be determined in the implementation stage. On the other hand, from the perspective of manufacturers who manufacture programmable controllers, it is not necessary to specially design controllers according to the order requirements of users in the manufacturing stage, which is suitable for mass production. Because of these characteristics, the programmable controller was quickly welcomed by the industrial control industry after its appearance and developed rapidly. At present, programmable controller has become a powerful tool for factory automation and has been widely used.

Users can read out the contents of RAM with a programmer, and can also write user programs into RAM. Therefore, ram is also called read / write memory. It is a volatile memory. After its power is disconnected, the stored information will be lost. Ram has high working speed, low price and convenient rewriting. In order to save the user program and some data (such as the count value of the counter) in RAM after turning off the external power supply of PLC, ram is equipped with a lithium battery. Some PLCs still use ram to store user programs. The lithium battery can be used for 2-5 years. When the lithium battery needs to be replaced, the "battery voltage is too low" led on the PLC panel will be on, and an internal flag bit will change to l state. Its normally open contact can be used to connect the indicator light or audible and visual alarm on the control panel to inform the user to replace the lithium battery in time. (2) Read only memory (ROM) the contents of ROM can only be read, not written. It is nonvolatile, and it can still save the stored content after the power supply disappears. ROM is generally used to store the system program of PLC. According to the scanning principle of PLC ladder diagram program, scan sentence by sentence and execute the program according to the step sequence from left to right, from top to bottom. When a program jump instruction is encountered, the jump address of the program is determined according to whether the jump condition is satisfied. When the user program involves the input and output status, PLC reads out the corresponding input terminal status acquired in the previous stage from the input image register, reads out the corresponding image register from the output image register, performs logical operation according to the user program, and stores it in the relevant device registers. We are committed to complete sets of electrical automation equipment and provide professional automation solutions for production lines. The company has successful experience in automation technology (especially in metallurgy industry and non-ferrous metal processing industry). We have cooperated with foreign parties for many times to complete the design, manufacture and commissioning of strip cold rolling, hot rolling and finishing equipment. The company also has successful experience in the transformation of old equipment. It makes rational use of the production gap of customers and completes the transformation and upgrading of old equipment, which saves money for customers and ensures normal production at the same time. For each device, the contents registered in the device image register will change with the program execution process. Supply chain transformation has opened a new era of real-time, end-to-end transparency and performance management. One of the keys to the development of this technology is RFID tags and readers, which help to automate the inventory process, simplify the workflow and speed up the operation of the production line. RFID solutions can also complement and integrate with emerging machine vision solutions to improve process accuracy and reliability. With the support of prediction and analysis, the company can predict the future demand of parts or finished products more accurately at the weekly level. Normative analysis provides clear guidance on what actions can or should be taken to protect the supply chain from relevant operational errors or potentially destructive events as far as possible.

This evolution of supply chain 4.0 is driven by significant advances in automation and traceability technologies. For example, RFID scanning technology updates the traditional two-dimensional barcode, improves productivity, and can be integrated with other solutions such as machine vision and predictive analysis. Fixed RFID readers will play an important role in the future warehouse environment. When combined with other advanced solutions, RFID technology can support the key economic drivers of warehouses or distribution centers, including asset visibility, productivity, quality control, tracking and traceability.

RFID technology has become more and more effective and cost-effective in the warehouse and logistics environment, making it more widely used. However, to achieve (ROI), we need to work with solution providers to help integrate technology into the business, so as to avoid isolated workflow and minimize complexity. Manufacturing plants are particularly suitable for the use of passive RFID readers, where materials usually follow a fixed path through the facility. The new wide area advanced RFID antenna can expand the scanning range to track the real-time location of every asset in the warehouse.

In discrete manufacturing, inventory is usually serialized, and each unique part has a dedicated location. Using RFID tags, the production manager can ensure that the materials are sorted correctly so that the correct components can enter the production line at the right time.

Improving visibility not only enables organizations to detect errors after they occur, but also helps prevent problems from happening and avoid potential quality control problems that may damage the company's reputation or profits. In addition, preventing asset utilization problems and strengthening the tracking of raw materials can help enterprises maintain the operation of production lines without affecting productivity. Supply chain transformation is not limited to one or several industries. Most of the same supply chain technologies can be applied to multiple industries -- from automobiles and clothing to pharmaceuticals and groceries, from manufacturing plants and warehouses to transportation, and then to final distribution points, such as retail stores and medical facilities. RFID solutions can help grocery stores, fast food restaurants, food suppliers and even hospitals significantly improve inventory visibility, reduce costs and reduce waste. Installing passive RFID readers in corridors such as porches or coolers can improve control capability and visibility without increasing labor costs. RFID can also improve the traceability of the drug supply chain and integrate with temperature monitoring solutions to provide more detailed information.

The frequency can be gradually increased by running under scalar to observe whether the current fluctuation is large. Storage requirements:

The storage of spare modules should meet the following requirements: all modules must be packaged with anti-static bags and stored or stored according to the requirements of the manufacturer, and the temperature and humidity of the module storage room should also meet the requirements of the manufacturer; Anti static measures shall be taken when accessing the modules. It is forbidden to touch the circuit board with hands at any time, and registration shall be carried out, and entry and exit procedures shall be handled.

2 regular inspection

A small number of common spare parts kept by the discipline shall be inspected every six months. The inspection contents are as follows:

(1) The surface is clean, the printed board plug-in is free of oil stain, the printed board plug-in is free of oil stain, and there is no abnormality after slight tapping.

(2) The software loading and unloading test is normal, and the communication port and manual operation station work normally.

(3) Various analog and switching input and output channels work normally.

(4) Load the test software and work normally for no less than 48h.

(5) Switching test of redundant modules.

(6) After the inspection, the inspection record shall be filled in and the qualified mark shall be pasted.

3 pre use inspection

Before the module is put into operation, check whether the communication ports, I / O functions and control algorithm functions meet the requirements; Check the status of the module on the engineer station and it meets the requirements; Load the configuration into the module and check whether it is correct.

4. Confirmation when putting into use

When putting into use, the module address and other switches shall be set and confirmed by the supervisor before inserting the correct module position and filling in the record card.

你的满意是我们不懈的追求;

你的口碑相传是对我们好的回报;

我们赚合理利润,做长久生意,交真心朋友;

ABB PCD230A

ABB GDB021BE05 HIEE300766R0005

ABB PU516

ABB 3HNE 00313-1 TILLV.0317 机器号:64-25653

ABB 560CMU05

ABB DSIH 72VP ENOK

ABB SPAD346C

ABB UFC760BE42

ABB PCD230A

ABB 81EU01E-E

ABB PCD231B101

ABB PCD231B101

ABB DSPC172

ABB UFC760BE1142

ABB CI858

ABB 086351-004

ABB DTCC901B

ABB DO610

ABB SC520

ABB AO610

ABB UNITROL 1010

ABB 5SHX08F4502

ABB PFSK151

ABB IT94-3 HESG440310R2 HESG112699/B

ABB DSRF182AK02 3BSE014078R1

ABB PP826

ABB PFSK152

ABB PPC380AE102

ABB SC510 3BSE003832R1

ABB TAS.580.0600G00 V01

ABB 5SHY35L4520 5SXE10-0181 AC10272001R0101

ABB AI620

ABB 5SGY3545L0020

ABB 3ASC25H209

ABB PM861AK01

ABB GFD212A

ABB 3HAB8101-19 DSQC545A

ABB YYT107A

ABB 3HNA023093-001

ABB EI813F

ABB 5SHX1445H0001

ABB GDD471A001

ABB 3HAC17484-8108

ABB 5SHX2645L0004

ABB UFC718AE101

ABB INNPM12

ABB DCP10

ABB 5SHX1960L0004

ABB AO845A

ABB 086351-004

ABB DSDP170

ABB UNS2882A

ABB UNS2881B-P V1

ABB TP858

ABB SD802F

ABB GDD471A001

ABB IMASI23

ABB UCD224A103

ABB FI840F

ABB DSQC627 3HAC020466-001

ABB V18345-1010521001

ABB XI16E1

ABB AO845

ABB PS130/6-75-P

ABB CI610

ABB 5SHY35L4520

ABB 5SHY3545L0009

ABB YB560100-EA S3

ABB IMFEC12

ABB LT8978bV1

ABB PM861AK01

ABB PPC905AE101

ABB DSMB-01C 3AFE64691929

ABB 3HAC17346-1/01

ABB IC660BBA104 6231BP10910

ABB V4550220-0100

ABB UNS0119A-P,V101

ABB CI868K01-eA

ABB PDD500A101

ABB 5SHY35L4510

ABB UFC760BE41

ABB GVC736CE101

ABB 3HAB3700-1

ABB NMTU-21C

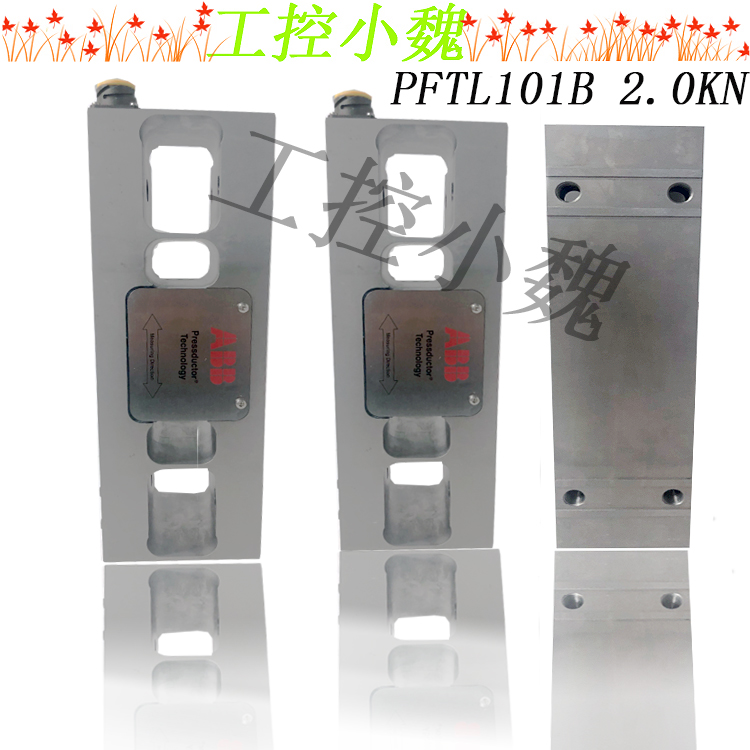

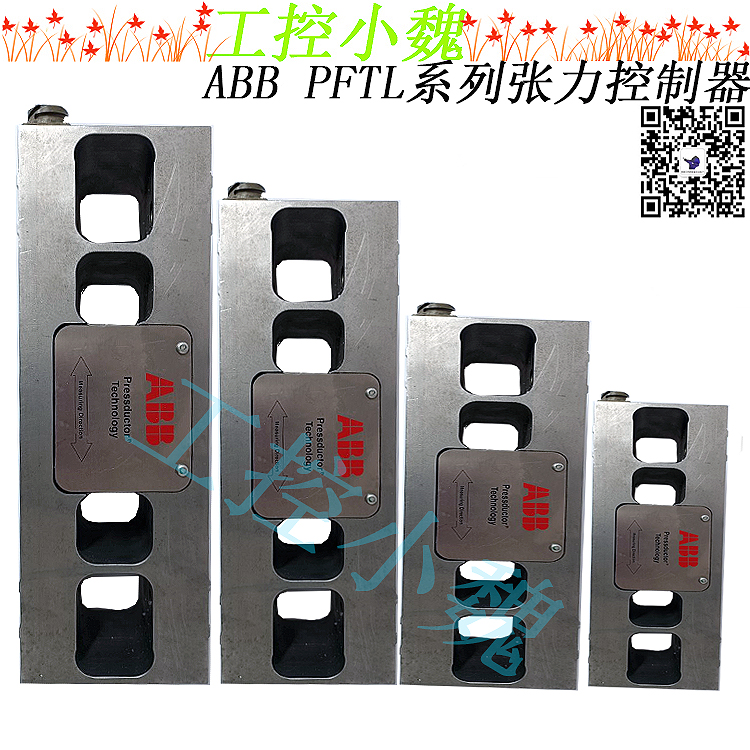

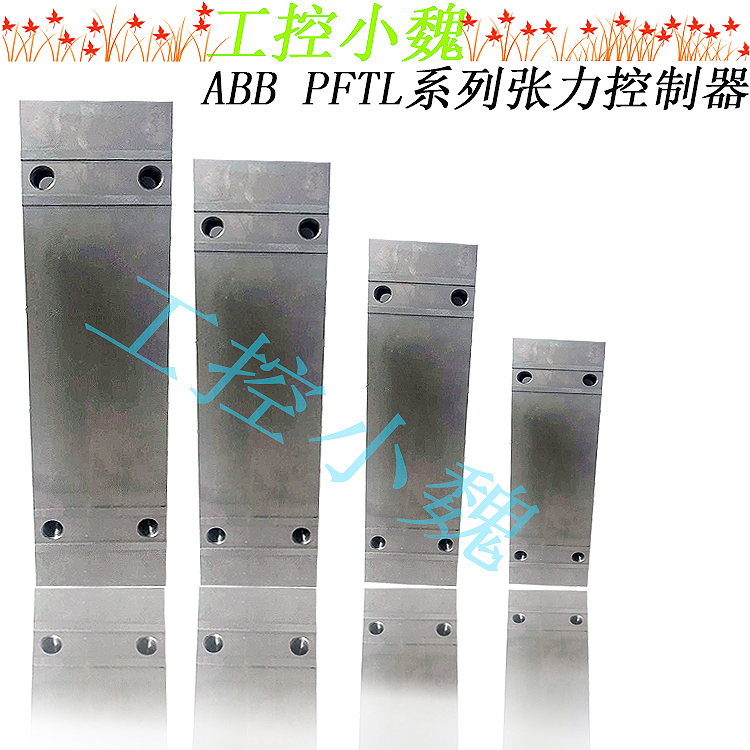

ABB PFCL201C 20KN

ABB CS513 3BSE000435R1

ABB PFSK152

ABB PFSK151

ABB 3ASC25H204

ABB DDI01

ABB DSMB-02C 3AFE64666606

ABB 5SDF0860H0003

ABB 216AB61

ABB ARCOL 0339

ABB PDD200A101

ABB PM825 3BSE010796R1

ABB SPBRC410

ABB INNIS21

ABB DSQC352

ABB 81EU01H-E

ABB DPW01

ABB UFC721BE101

ABB PM861AK01

ABB REF610C11LCLR 60HZ

ABB 5SGX1060H0003

ABB 07KT97F1

ABB INNIS01

ABB 5SHX10H6004

ABB SPAJ110C

ABB DSAI130D 3BSE003127R1