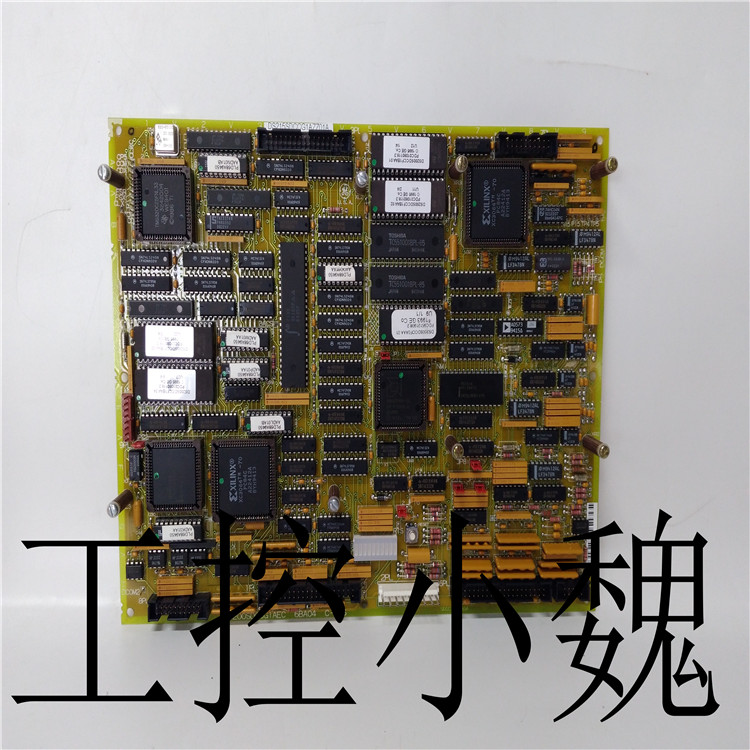

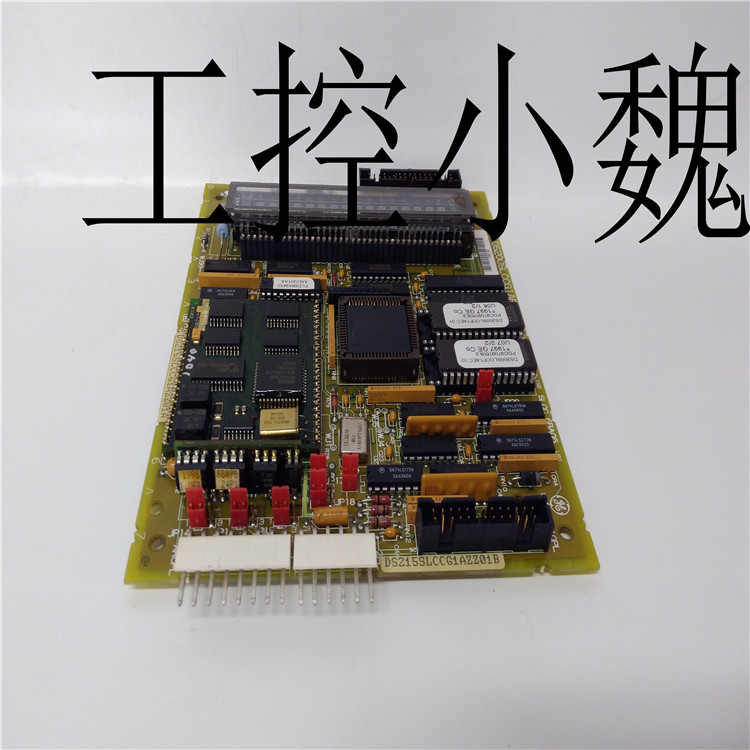

IS200ECTBG1ADE工作原理及应用型号简介

(一)建立现代化教学管理体系

通过利用计算机科学与技术建立教学管理体系,从而提高学校对学生的管理效率。例如,学校可以利用计算机技术建立学生档案,包括学生的个人基本信息、兴趣爱好等,这对教师在教学工作中实施针对性教学具有重要意义,同时有助于提升学生管理工作的质量。其次,还可以通过利用计算机技术建立课程评价体系,学生在学习结束后可以利用网络对教师的课堂教学工作做出点评,从而有助于学校更合理地设置课程。0后,提高管理教师队伍质量[2]。教师在实际教学过程中可以通过利用计算机科学与技术开会,减少了不必要的时间浪费,有助于提高教师绩效考核的准确度。

(二)提升现代化教学模式质量

首先,通过在初中教学工作中应用计算机科学与技术,能够转变传统教学模式,提高现代化教学的质量。初中教学过程中,在传统的教学模式下,有限的教学时间无法确保学生对知识难点、重点进行更好的把握,而通过计算机科学技术展开教学,学生在学习新知识之前可以做好课前预习工作,同时,教师也可以明确学生的知识预习掌握情况,有助于在课堂教学中为学生实施针对性教学,从而提高学生成绩。其次,教师教学过程中利用计算机科学与技术,将各个学科枯燥乏味的理论知识转变为生动的情境,使知识能够在学生脑海中形成画面,提高学生对知识的学习兴趣。0后,在教学中利用计算机科学与技术,能够提高学生的自主学习能力,有助于学生形成独立思考的思维模式[3]。

三、结语

在初中教学中,应用计算机科学与技术是时代发展的必然需求。在课堂教学中,通过计算机科学与技术的现代化应用,促使学生积极分享生活中的学科知识,为学生提供交流讨论的平台,对培养学生的创新思维以及自主学习能力有一定的积极意义,有助于提高教学效率。GE 发电机管理继电器的部件号 489-P5-HI-A20-E 中的 E 代表什么? 部件号 489-P5-HI-A20-E GE 发电机管理继电器中的 E 代表增强型显示器,其 LCD 比基本显示器更大。

如何更改值的范围? 按下帮助按钮,它将显示有关设定点的敏感内容。值的范围以及如何更改设定值在帮助消息中。

489-P5-HI-A20-E GE发电机管理继电器如何显示发电量? 在部件号为 489-P5-HI-A20-E 的发电机管理继电器上,产生的功率为正瓦特。按照惯例,感应发电机通常需要无功功率,形成励磁系统。

489 发电机管理继电器有什么作用? 489 GE 发电机管理继电器管理发电机的同步和感应,它是一种基于微处理器的继电器,旨在保护和管理发电机。

基于微处理器或固态继电器通常用于提供多种设置和曲线选项。

介电耐压是参考标准 EN60255-5。

耐冲击电压是参考标准 EN60255-5。

绝缘电阻为参考标准 EN60255-5。

阻尼振荡是参考标准 IEC61000-4-18/IEC60255-22-1。

静电放电是参考标准 EN61000-4-2/IEC60255-22-2。

RF 抗扰度是参考标准 EN61000-4-3/IEC60255-22-3。

快速瞬态干扰是参考标准 EN61000-4-4/IEC60255-22-4。

浪涌抗扰度是参考标准 EN61000-4-5/IEC60255-22-5。

传导射频抗扰度是参考标准 EN61000-4-6/IEC60255-22-6。

辐射和传导发射是参考标准 CISPR11/CISPR22/IEC60255-25。

正弦振动是参考标准 IEC60255-21-1。

电源磁抗扰度为参考标准 IEC61000-4-8。

电压骤降和中断是参考标准 IEC61000-4-11。

入口保护是参考标准 IEC60529。

环保(冷)是参考标准IEC60068-2-1。

环保(干热)参考标准IEC60068-2-2。

相对湿度循环是参考标准 IEC60068-2-30。

EFT 是参考标准 IEEE/ANSI C37.90.1。

阻尼振荡是参考标准 IEEE/ANSI C37.90.1。

ESD 是参考标准 IEEE/ANSIC37.90.3。

安全性是参考标准 UL508、UL C22.2-14 和 UL1053。

相对湿度循环是参考标准 IEC60068-2-30。

EFT 是参考标准 IEEE/ANSI C37.90.1。

阻尼振荡是参考标准 IEEE/ANSI C37.90.1。

ESD 是参考标准 IEEE/ANSIC37.90.3。

安全性是参考标准 UL508、UL C22.2-14 和 UL1053。

相对湿度循环是参考标准 IEC60068-2-30。

EFT 是参考标准 IEEE/ANSI C37.90.1。

阻尼振荡是参考标准 IEEE/ANSI C37.90.1。

ESD 是参考标准 IEEE/ANSIC37.90.3。

安全性是参考标准 UL508、UL C22.2-14 和 UL1053。一、事例

有一个客服工单体系,会从邮件服务器中获取客服邮箱收到的邮件,而且将这些邮件主动生成工单并主动分配给相应的客服组,每次客服人员从工单列表中选取一个工单进行处理,每处理一次就会发生一个工单处理记载,直到工单被客服封闭间断。

该体系现已运行了一年,在这一年中一共发生了一千万个工单和五千万条工单处理记载。因为全部工单和处理记载都存储在一个数据库中,因而每次客服查看工单列表时会很慢,可是客服还能忍耐。直到某天,公司选择将其他几种类型的客服邮件也都参加到客服工单体系中,就呈现了很大的问题,工单数量急剧增加,导致工单列表翻开速度越来越慢,乃至构成客服工单体系溃散。

开发人员收到反应后,剖析如下:

工单数量每天的增加量是本来的3倍;

工单总量现已超越3000万;

工单处理记载现已过亿。

依据上面的剖析,不难看出是因为数据量过大构成的,所以开发人员进行了0常见的操作:优化库结构、优化体系代码、加索引等操作。虽然体系不再呈现溃散的状况,可是工单列表的查询依然很慢。经过开发组内部评论,拟定了如下两个计划:

数据库分区

数据冷热别离

下面咱们就来具体看一下这两种计划的思路和优缺点。

二、数据库分区

2.1 什么是分区

分区,并不是呈现新的数据表,而是在不创立新表的状况下,将表中的数据依照必定规矩分配存储到不同的位置(硬盘、体系乃至是服务器中)。

Tip:因为本专题阐明的是架构常识,因而在大部分状况下不会涉及到某项技能、某种言语的阐明。

数据库分区有如下四个利益:

分区能够存储更多的数据,因为表中数据都被存储在的不同的硬盘、体系或服务器中;

跟着数据的增加,能够随时增加新的分区来存储数据;

在整理数据的时分,能够直接删去分区;

优化了查询速度,每次查询数据时咱们不需求查询全部数据,只需求查询特定分区即可,例如数据表依照日期分区,每个年月是一个分区,那么当咱们查询某年某月的数据时,只需求一个分区的数据即可(当然,这儿说的查询或许不谨慎,这儿仅仅举例子算了,不用介怀,关于查询的处理我将在后边的文章中介绍)。

那么该怎样分区呢?下面咱们就以客服工单体系为例来阐明一下。

随着特大城市的出现

更环保的电气解决方案

成为全球电气行业的共同追求

它将在低碳发展中起到举足轻重的作用在过去,中压气体绝缘电气设备通常采用SF6作为绝缘气体,SF6具有良好的绝缘性能,满足用户对可靠、稳定的需求,但它也同时是一种强效温室气体,100年的GWP值可达23900,在大气中的影响时间将长达3000多年。

通过ABB和3M多年的联合研究,我们开发出一种可持续的SF6替代气体:AirPlus™,这是ABB突破性的创新,一种首创的混合气体 ,可将温室效应潜能值降低近100%。这种绿色、可持续的SF6替代气体则在环保型气体绝缘开关设备 ecoGIS™中得以运用。AirPlus™由约85%的干燥空气和15%的3M Novec™ 5110 绝缘气体组成,GWP(全球变暖潜能值)小于1,相比SF6气体,降幅超过 99.99%,大幅提升了中压开关设备的气候友好性。

以一个有20台40.5kV开关设备的典型站为例,采用以上环保气体方案后,在其全生命周期内合计可以实现2550吨CO2的碳减排,这相当于约14万颗松树在1年内吸收的CO2总量。

使用AirPlus™ 环保气体的ecoGIS™设备采用微正压运行可提高安全性并延长正常运行时间,更低的材料应力水平和更低的泄漏或故障风险,意味着开关柜在整个生命周期内都具备高效的性能。顺应“双碳”目标的要求,全球对ecoGIS™ 的需求在不断增长,自2015年以来ecoGIS™ 解决方案已有9000多台成功应用在多个项目上,基于成熟技术所带来的可靠表现令ecoGIS™ 解决方案深受客户信赖。随着各国环保政策升级和相关法律法规出台,无SF6开关柜将成为趋势。为满足客户的个性化需求,ABB在多款开关设备中采用“Eco Ready理念”解决方案,用户可以在开关站建设时使用SF6作为绝缘介质,轻松通过AirPlus™ 进行环保升级。ecoGIS™ 在为经济发展

提供澎湃动力的同时

也为环境带来积极的改变

让您的开关设备变得“更绿色”

让可持续发展成为现实

书写安全、智慧和可持续的电气化未来

ABB一直在行动

2.2 针对客服工单体系的处理计划

在客服工单体系中,咱们有一个工单表,首要的表结构由:工单编号、工单创立日期、工单状况(进行中、无人处理、已封闭)、客服究竟操作时刻、究竟处理人以及究竟处理人地点组组成。针对工单表的查询操作如下:

客服查询无人处理的工单;

客服查询自己接手的工单;

客服组长查询本组的工单;

客服查询某个客户的工单;

客服主管/组长查询0近一个月完毕的工单。

为了结束在查询时只查询特定的分区,咱们需求在查询条件中包含分区字段,可是就现在而言这四个查询操作并没有共有的字段。那么,咱们就来创立这个分区字段,首要咱们来剖析一下哪些字段适合作为分区字段。

体系在邮件服务中获取到客服邮件后会创立工单;

客服需求查询无人处理的工单;

客服查询自己正在处理的工单;

客服主管/组长查询0近一个月工单完毕的状况;

工单处理完毕后,客服封闭工单。

剖析的这五个方面,呈现了三个适合做分区的字段:工单创立时刻、工单状况、客服究竟操作时刻。那么哪个或哪几个更适合做分区字段呢?依据上面的剖析可知咱们能够将工单状况和客服究竟操作时刻作为分区的字段,进行中、无人处理以及0近一个月内封闭的工单放在一个A分区中,超越一个月的已封闭的工单放在一个B分区中。经过这样的处理,工单列表的查询速度就有了质的前进,每次查询 SQL 语句只用去扫描A分区就能够了。

可是,假定要这样做的话要考虑如下几个点:

开发组是否具有数据库分库经历;

因为要在出产环境中分区,因而要考虑分区给出产环境带来的影响。

三、数据冷热别离

在学习数据冷热别离前咱们先来看一下底子概念

3.1 底子概念

冷热数据:

所谓的冷数据指的是不常用的,状况底子不变的数据,热数据指的是常常运用,而且会对其进行操作的数据。

冷热库:

存放冷数据的数据库被称为冷库,存放热数据的数据库被称为热库。

冷热别离:

在处理数据时,将数据依照冷热分为冷库和热库,在咱们的事例中工单表是热库。

3.2 冷热别离计划

冷热别离计划有两种,一种是冷热数据都运用同一种类型的数据库,另一种是将冷数据存储在NoSQL数据库中。下面们我来别离阐明一下。

3.2.1 计划一:同类型数库存储

一般来说这个计划能够处理大部分数据存储问题,而且冷热库运用的是相同的库结构,数据从热库搬迁到冷库时不用进行数据转化,而且代码部分改动较小。和数据库分区相同,咱们在实施这个计划前,需求考虑这几个问题:

怎样判别数据冷热;

冷热数据别离怎样触发;

冷热数据别离怎样结束;

冷热数据怎样运用。

下面就针对这4个方面进行阐明

3.2.1.1 怎样判别数据冷热

常见的判别办法是,依据主表中的一个或几个字段来判别。比方在工单体系中,能够运用工单状况、客服究竟操作时刻来作为冷热数据的判别条件,将现已封闭的而且超越一个月的工单视为冷数据,其他的工单视为热数据。

在判别冷热数据中,咱们应遵循以下原则:

数据一旦被搬迁到冷库中,就代表事务代码只能对它进行查询操作;

冷热数据不能一起读取。

3.2.1.2 冷热数据别离怎样触发

触发冷热数据别离的办法有三种:在批改操作的代码后边加上触发冷热别离的代码、监听数据库改动日志、守时扫描数据库。针对这三种办法来一一阐明。

Pm511v16 3bse01181r1 is a high-performance programmable controller, whose speed, capacity, performance and function have reached a new level. ● CPU, power supply, input and output integration, built-in high-speed processing and positioning functions. Pm511v16 3bse01181r1 input and output can be expanded to 384 points at most. Powerful expansion functions can be realized through function expansion board and special adapter. I/o acquisition module is adopted. The module can be installed near the sensor end and connected with PLC through a group of communication lines, which not only saves the cost of wiring, but also saves the i/o points of PLC itself. If the field budget of pm511v16 3bse01181r1 is limited, it is obviously more economical to use i/o acquisition module. Modular structure, providing 14 to 128 point input / output range, and can also add extended special function modules (such as analog input / output). The pm511v16 3bse01181r1 transistor output type has two 100kHz pulse sequences for servo positioning applications.

IRB 260 robot is mainly designed and optimized for packaging applications. Although it is small and can be integrated into compact packaging machinery, it can meet all your requirements in terms of reach distance and payload. With abb motion control and tracking performance, the robot is very suitable for flexible packaging systems.

Strong reliability &mdash& mdash; IRB 260 robot with long normal operation time is designed based on IRB 2400 (with more than 14000 installed) which is the most widely used industrial robot in the world.

Fast &mdash& mdash; Short operation cycle time the robot is optimized for packaging applications and equipped with ABB's unique motion control function, which greatly shortens the packaging cycle time.

High accuracy &mdash& mdash; The production quality of parts is stable. The robot has extremely high accuracy. Coupled with ABB's excellent conveyor belt tracking performance, its picking and placing accuracy is first-class whether it is in fixed position operation or in motion operation.

Powerful &mdash& mdash; Wide range of application the robot is optimized for packaging applications, with small size, fast speed and a payload of up to 30kg.

Rugged &mdash& mdash; Suitable for harsh production environment, suitable for harsh environment applications, and the protection grade reaches IP 67.

Good versatility &mdash& mdash; Flexible integration and production the robot is light in weight and low in height, which is easy to be integrated into compact packaging machinery. It has been optimized according to the packaging application, which is the inevitable choice of robot automation. Equipped with a full set of auxiliary equipment (from integrated air and signal system to gripper), abb packaging software pickmastertm can be used together. The mechanical integration is simple, and the programming is very convenient.

In 1974, ABB (then known as Asea) introduced the IRB 6, the first fully electric robot. Today, ABB has nearly 30 models of robots that meet the production needs of a wide range of industries, supported by powerful system integration capabilities and a global sales and service network in 53 countries. Recently, abb signed a supply agreement with Aker solutions, the leader of sustainable energy solutions, to provide major electrical, automation and safety systems for the northern lights project in Norway. Aker solutions is the EPC contractor of the project. The project is the first industrial carbon capture and storage project jointly constructed by Norwegian national oil company equinor, shell and total energy. It aims to develop an open and flexible infrastructure to safely store carbon dioxide emitted by European industry. The first phase of the project is planned to be completed in the middle of 2024, when 1.5 million tons of carbon dioxide will be permanently stored every year, and the storage capacity of the second phase of the project will be expanded to more than 5 million tons per year. ABB's automation, electrical and digital solutions will be an important part of the aurora borealis project to help the new carbon capture terminal achieve remote operation and ensure efficient operation of the facility. With ABB's industry-leading distributed control system ABB ability ™ With the system 800xA, operators will be able to have a clearer understanding of the operation of the aurora borealis storage facilities. The real-time and historical data analysis capabilities provided by ABB system can instantly present the operation data and KPIs of the plant, so as to help operators make more accurate and wise decisions and choose the best asset and process performance optimization scheme. Abb is not only the market leader of distributed control system, but also our long-term trusted partner. It has a comprehensive understanding of our business and expertise in land, sea and seabed projects. This is our key consideration in selecting suppliers. We must entrust important remote operations to partners with rich successful experience in reliability and performance optimization, so as to lay a solid foundation for this important development plan.

In order to achieve 1.7 billion tons of carbon dioxide capture by 2030 and achieve net zero emissions by 2050, industrial carbon capture and storage capacity is undoubtedly crucial in view of the current inability to curb industrial carbon emissions. Aurora Borealis is a significant development plan, which not only helps to rebalance the carbon cycle, but also demonstrates the spirit of innovation. We are delighted to participate in this inspiring project and contribute to a safer, smarter and more sustainable future. The special transport ship will transport the captured and liquefied carbon dioxide from the emission site to the aurora borealis Ø ygarden storage facility in western Norway, and conduct remote control through equinor's sture terminal facility located about 7 kilometers away. In order to realize remote operation, abb will establish an advanced extended operator workstation in the aurora borealis storage facility, which will work together with sture's central control room to significantly shorten the response time through seamless communication and provide 24/7 remote operation.

ABB will not only provide shore power solutions, but also deploy the main electrical system through the power process management system and the integration of high and low voltage switchboards and transformers to provide power support for the whole project. From July 7 to July 10, abb appeared at the first Xiamen International Red Power new grid equipment exhibition, bringing the world's leading digital distribution solutions. This exhibition focuses on building a tight circulation platform on the supply side and demand side of China's power and electrical industry, and jointly building a new power system with the upstream and downstream of the supply chain to help achieve the "double carbon" goal.

ABB showed its leading medium and low voltage distribution products and system solutions, including ABB unigear ZS1 500mm wide medium voltage air insulated metal enclosed digital switchgear, primegear zx0 environmentally friendly gas insulated switchgear, and neogear ™ Laminated busbar scheme low voltage switchgear, ivd4 ® Innovative products and solutions such as medium voltage intelligent solutions show ABB's leading technical support for achieving China's "carbon neutrality" goal. To achieve the goal of "double carbon", we need to build a new power system with new energy as the main body. Through the Multi Strategy precise tuning innovative solution of ABB zee600 smart energy management center, we can realize the flexible and precise regulation of "source network load storage", and create a green, low-carbon, strong, reliable, intelligent, efficient, safe and comfortable smart park. Through AI big data analysis and optimization and precise regulation and management, we can maximize the local consumption of clean energy, Improve energy efficiency and help achieve carbon emission reduction goals. ABB unigear ZS1 500mm wide switchgear, a complete set of power Internet of things solutions for medium voltage air insulated switches, is only 500mm wide, with withdrawable circuit breakers, which reduces the floor area by 25%, realizes the pre assembly of two sets and improves the efficiency of on-site installation. Using ABB ability ™ Cloud technology "cares" the health of equipment throughout its life cycle, and realizes the leap forward transformation from passive operation and maintenance and preventive detection to predictive maintenance.

ABB primegear zx0 is a 10/24kv environment-friendly digital gas insulated switchgear launched by ABB in the era of digital economy and double carbon based on mature technology and in line with the concept of modern green development. This product inherits the advantages of existing GIS products and has achieved new breakthroughs in environmental protection, safety, reliability, miniaturization and intelligence. The product can be widely used in residential power distribution, rail transit, commercial construction, industry, highways, bridges and tunnels and other fields. ABB NeoGear ™ Low voltage switchgear is a revolutionary innovation of ABB group. Latest neogear ™ The switch cabinet adopts the innovative four pole laminated busbar scheme, combined with abb ability ™ The connectivity and digital capability of the platform can reduce the occupied space by 25%, reduce the heating capacity by 20%, and reduce the operation and maintenance cost by 30%.

This switch cabinet also has a "higher level" safety design. The full insulation design ensures the safety protection of all live parts. The bus components used are 92% less than those of traditional switchgear, and the electrical connectors are 90% less. On the basis of reducing costs and improving operation and maintenance efficiency, making switchgear safer has become an ideal choice for power, food and beverage, data center and other industries. In addition, ivd4 ® The medium voltage intelligent solution was also presented at the exhibition. It realized the deep integration of VD4 Vacuum Circuit Breaker with sensors and monitoring units. The integrated solution is ready to use, helping customers realize the perception of switchgear status more smoothly and intuitively. The accurate evaluation system provides targeted operation and maintenance suggestions, and brings customers a better, more reliable and safer intelligent distribution operation and management experience. High current type

The circuit topology is named for the use of inductive elements in the DC link of the low-voltage converter. The input side adopts thyristor phase-shifting control rectification to control the current of the motor, and the output side adopts forced commutation to control the frequency and phase of the motor. It can realize the four quadrant operation of the motor.

High voltage type

The step-down transformer is introduced in the front section to step down the power grid, and then connect the low-voltage frequency converter. The input side of the low-voltage frequency converter can adopt silicon controlled phase-shifting control rectification, or two tube three-phase bridge direct rectification, and the middle DC part adopts capacitor smoothing and energy storage. IGBT components are often used in inverter or converter circuits. Through SPWM transformation, alternating current with variable frequency and amplitude can be obtained, and then transformed into the voltage level required by the motor through step-up transformer. It should be pointed out that a sine wave filter (f) needs to be placed between the converter circuit and the step-up transformer, otherwise the step-up transformer will heat up due to excessive input harmonics or dv/dt, or damage the insulation of the winding. The cost of this sine wave filter is very high, which is generally equivalent to 1/3 to 1/2 of the price of low-voltage inverter.

High frequency conversion

The high-voltage converter does not need the voltage rise and fall transformer, and the power device directly constructs the converter between the power grid and the motor. Because the problem of withstand voltage of power devices is difficult to solve, the current direct method is to use devices in series to improve the voltage level. Its disadvantage is that it needs to solve the problem of voltage equalization and buffer of devices, which is complex and difficult. However, this kind of frequency converter has no voltage rise and fall transformer, so its efficiency is high, its mode is high, and its structure is relatively compact.

Vector controlled high-voltage inverter has also been applied.

Current situation abroad

Major foreign frequency converter manufacturers have formed a series of products, and their control systems have also achieved full digitalization. Almost all products have vector control function, and the perfect process level is also a foreign feature. In developed countries, as long as there are motors, there will be frequency converters at the same time. Its current development is mainly shown as follows:

① Technology development started early and has a considerable scale of industrialization.

② The frequency converter that can provide extra large power has exceeded 10000kw.

③ The technical standards of frequency conversion and speed regulation products are relatively complete.

④ The supporting industries and industries related to frequency converters have begun to take shape.

⑤ It can produce power devices in frequency converters, such as IGBT, IGCT, sgct, etc.

⑥ High voltage inverter is widely used in various industries and has achieved remarkable economic benefits.

⑦ Internationalization and localization of products have intensified.

⑧ New technologies and processes emerge in endlessly, and are widely and rapidly applied to products.

Future situation

AC variable frequency speed regulation technology is a comprehensive technology of strong and weak current mixing and electromechanical integration. It not only deals with the conversion of huge electric energy (rectification and inversion), but also deals with the collection, transformation and transmission of information. Therefore, it must be divided into two parts: success rate and control. The former should solve the technical problems related to high voltage and large current, and the latter should solve the software and hardware control problems. Therefore, in the future, high-voltage variable-frequency speed regulation technology will also be developed in these two aspects, mainly as follows:

① High voltage inverter will develop in the direction of high power, miniaturization and lightness.

② High voltage inverter will develop in two directions: direct device high voltage and multiple superposition (device series and unit series).

③ New power semiconductor devices with higher voltage and greater current will be used in high voltage converters.

④ At this stage, IGBT, IGCT and sgct will still play a major role, and SCR and GTO will withdraw from the inverter market.

⑤ The application of speed sensorless vector control, flux control and direct torque control will be mature.

⑥ Fully realize digitization and automation: parameter self setting technology; Process self optimization technology; Fault self diagnosis technology.

⑦ The application of 32-bit MCU, DSP, ASIC and other devices to achieve high-precision, multi-function inverter.

⑧ Relevant supporting industries are moving towards industrialization and large-scale development, and the social division of labor will be more obvious. With the further deepening of technical research, domestic high-voltage converters can be compared with imported converters in theory and function, but due to the limitations of technology, the gap with imported products is still obvious. These conditions are mainly reflected in the following aspects:

① Major foreign products are stepping up their occupation of the domestic market and accelerating the pace of localization.

② The R & D capacity and industrialization scale are increasing year by year.

③ The power of domestic high-voltage inverter is also increasing. At present, the domestic application has achieved 20000KW.

④ The technical standards of domestic high-voltage inverter need to be standardized.

⑤ The industry supporting high-voltage inverter is very underdeveloped.

⑥ The production process is general, which can meet the technical requirements of frequency converter products, and the price is relatively low.

⑦ The key components of power semiconductors used in frequency converters are completely imported, and will be imported for a long time.

⑧ The technological gap with developed countries is narrowing, and products with independent intellectual property rights are being applied in the national economy.

⑨ A frequency converter with the functions of instantaneous power failure recovery and fault recovery has been developed